CAPABILITY

Concept design

Based on our long experience in designing a wide range of blow molding spoilers, MOYA provide the best design to meet customer needs. MOYA provides the best design for products to meet Aero-dynamics elements and various regulations, while enhancing the styling of the vehicle.

Engineering Design

Based on more than 25 years of experience in blow molding engineering design, MOYA does product design to reflect the our customer’s concept design. Our experience and patents give Moya a competitive advantage to develop and manufacture advanced and novel designs. Moya’s team of design, tooling, molding and production engineers collaborate to evaluate all the steps to produce the part from mold design to check fixture design and packaging.

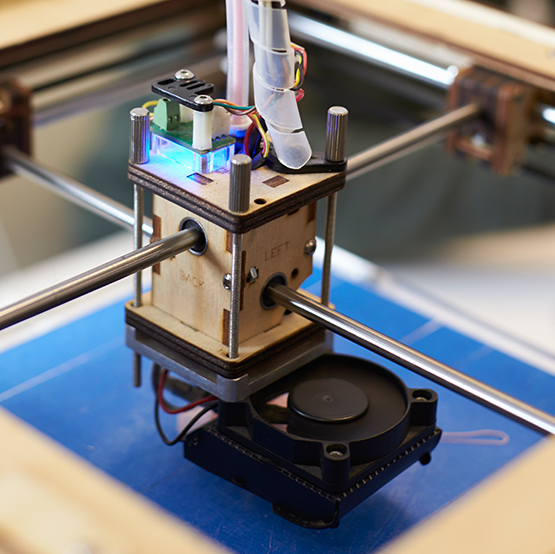

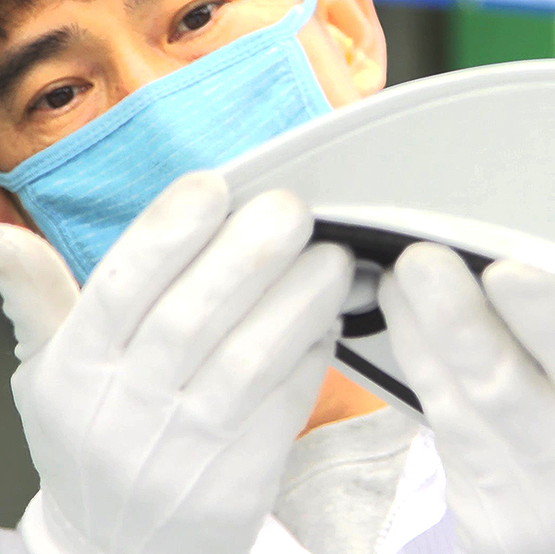

Prototyping

Based on the concept design, we build prototype samples to confirm our engineering designs before making the mold and going into production. By checking the samples in real size before building the mold, we can check the surface match with the vehicle, find potential assembly problems, develop packaging and confirm compatibility with various processes before mass production.

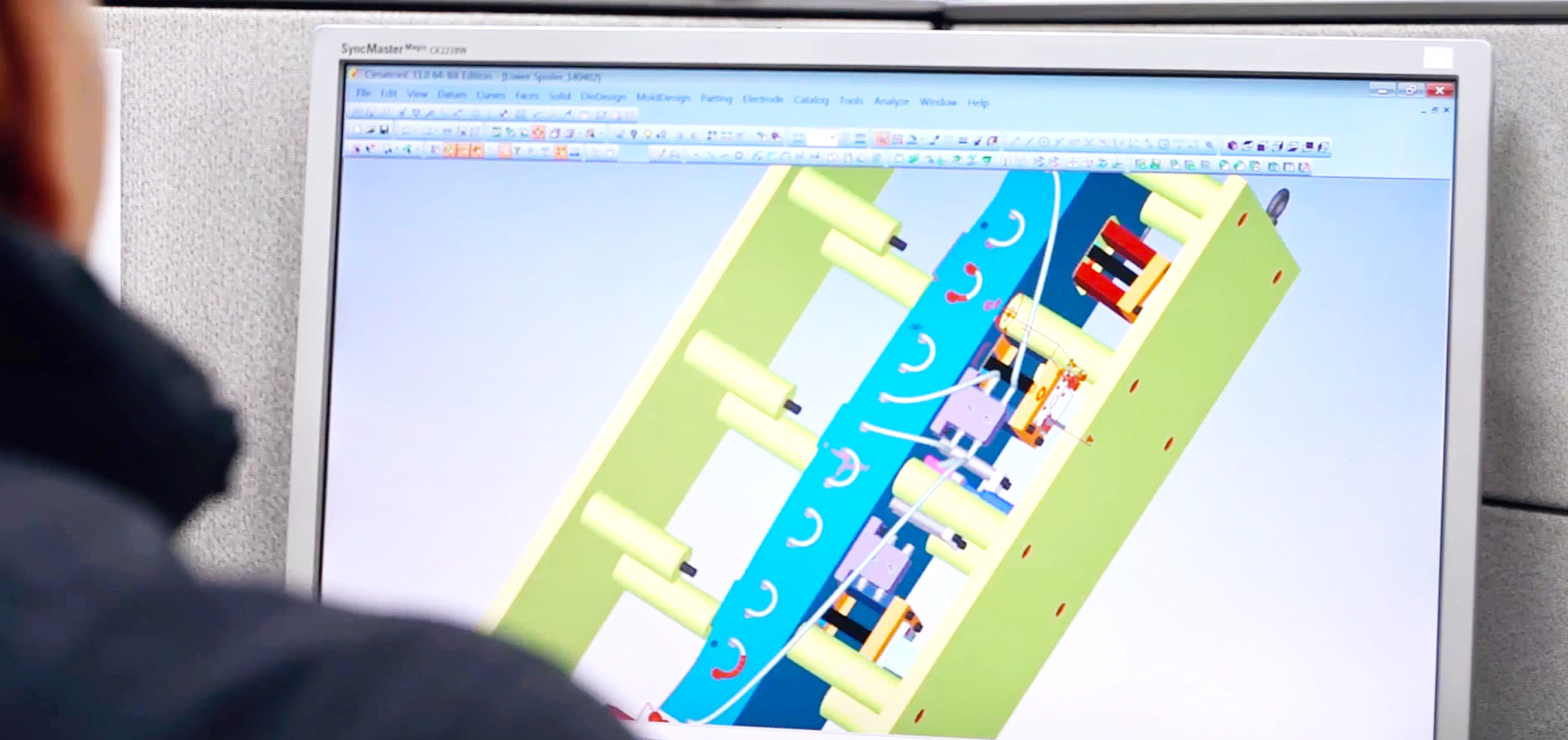

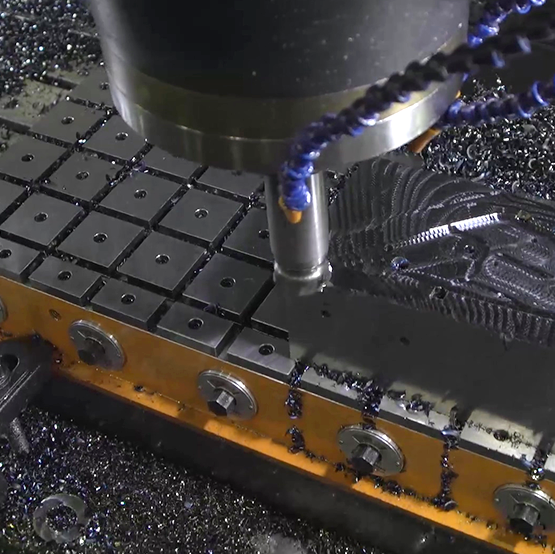

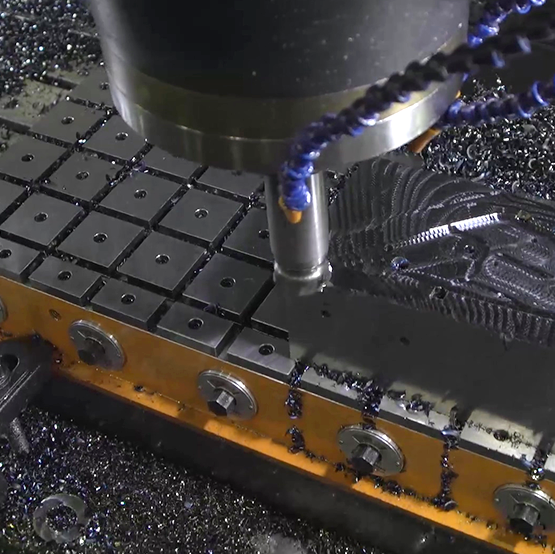

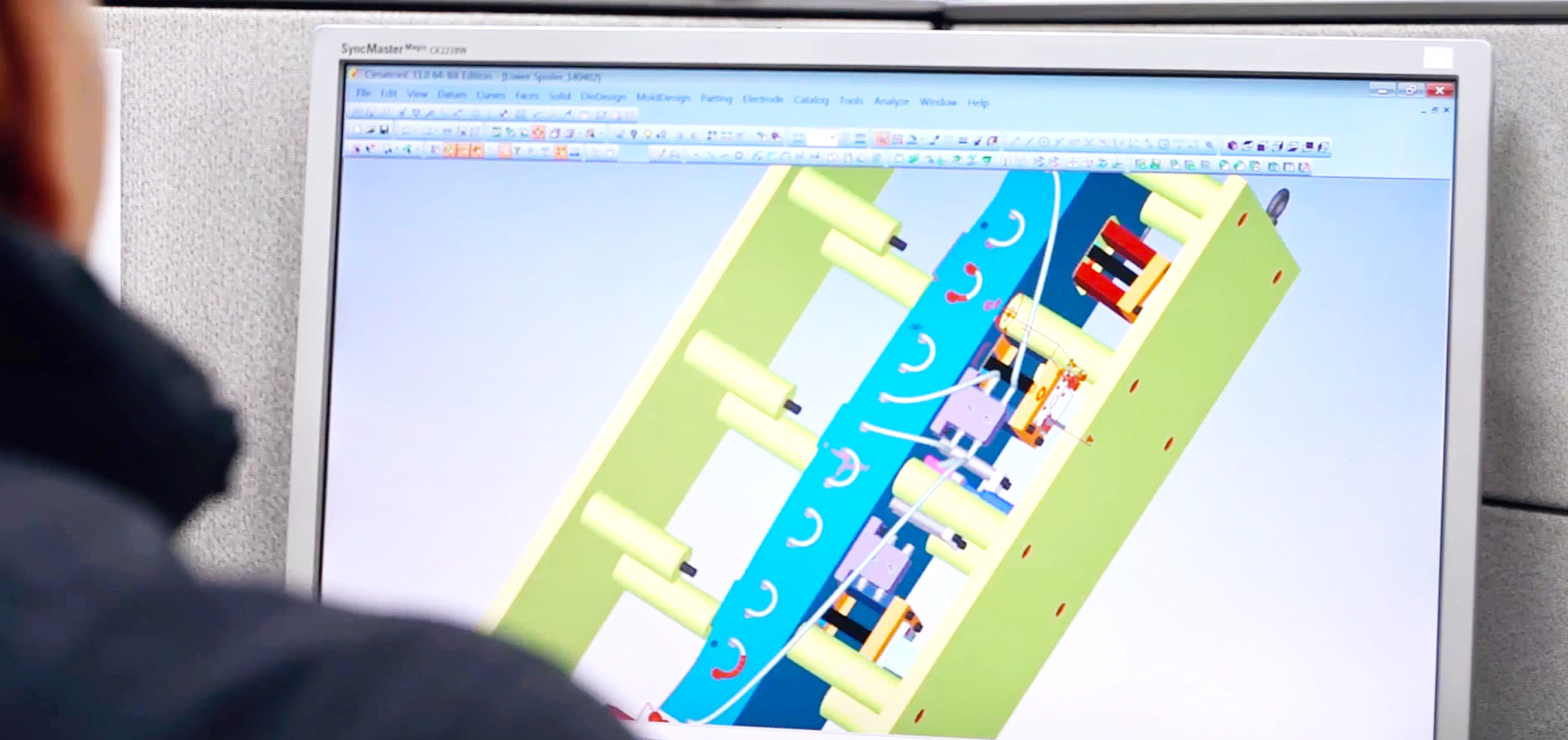

Tool Design

The mold design is optimized for the blow molding to produce a high quality part and built based on many years of Moya experience and patents available.

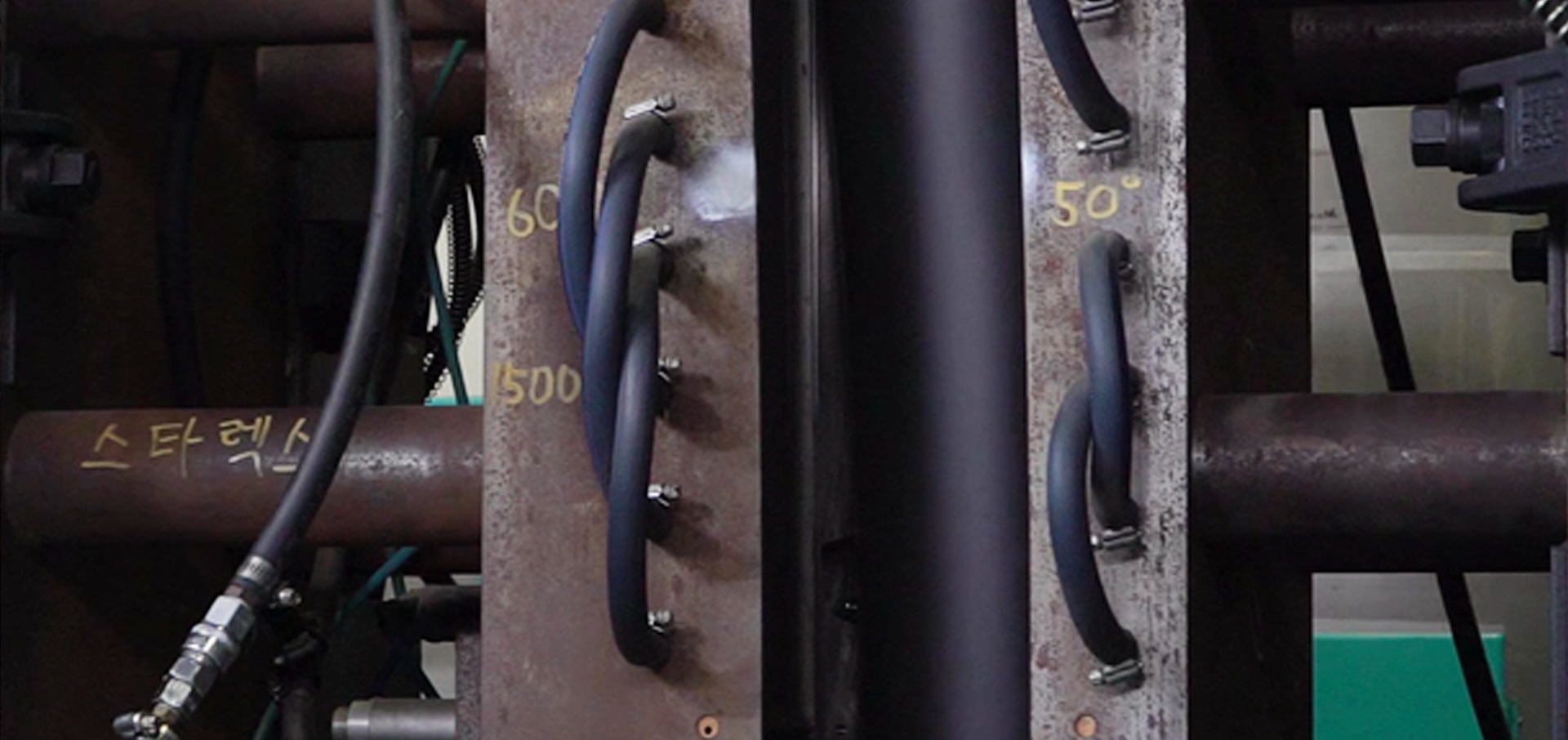

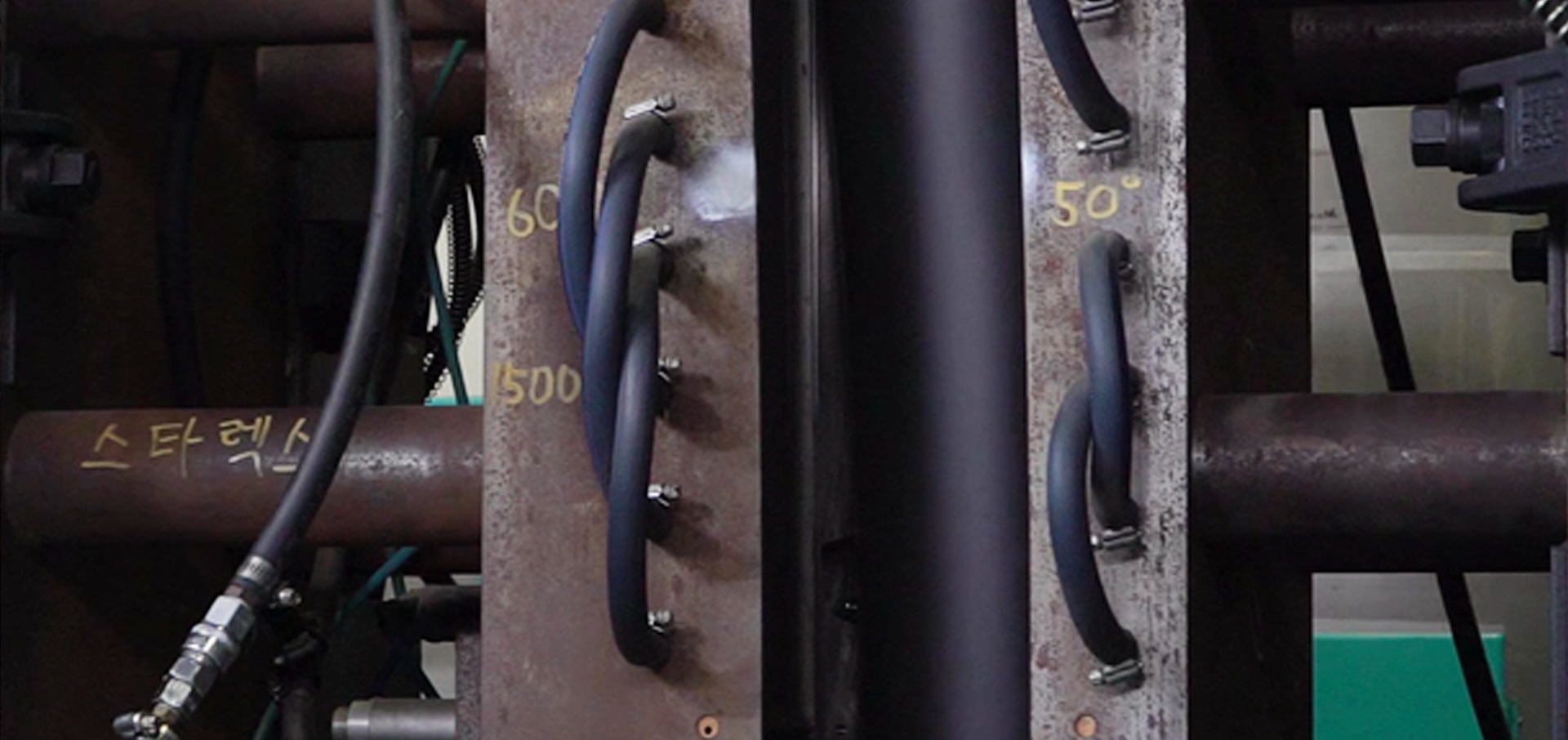

Blow Molding

Blow molding is a process to make plastic products with hollow structures. A hollow tube of molten plastic (parison) is extruded from the blow molder. The mold is closed around the parison and blow needles penetrate the parison to inflate it to the shape of the mold. The material is cooled, then the part is removed from the mold and trimmed. The hollow blow molded part is one piece and does not require bonding of two halves like the injection molded process. Blow molding has many advantages in strength, design, part reduction and assembly. Blow molds are less expensive than injection molds for the same finished shape. Moya has supplied the best world class blow molded spoilers and parts for 25 years.

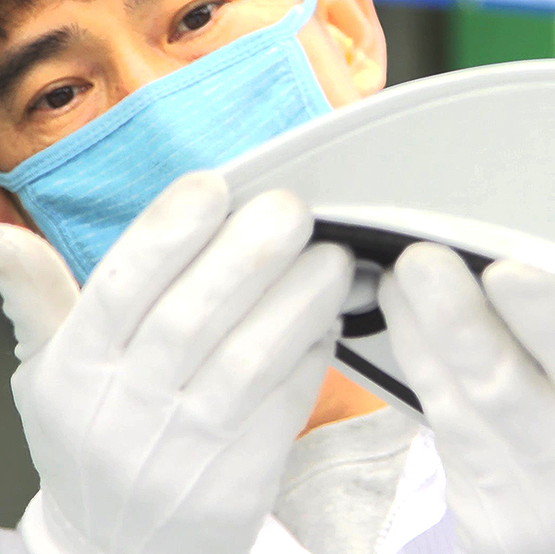

Sanding

Sanding the surface of the blow molded product makes the optimal surface condition for painting. MOYA has a long experience and know-how preparing the surface for good paint adhesion and a Class ”A” finish.

Painting

Moya operates two independent conveyor painting lines: top loading method and a floor loading method. Both painting lines are operated with top OEM quality painting levels and optimized for each product shape and painting method. With over 20 years of experience, our highly trained engineers and workers produce the best results for each product with our craftsmanship.

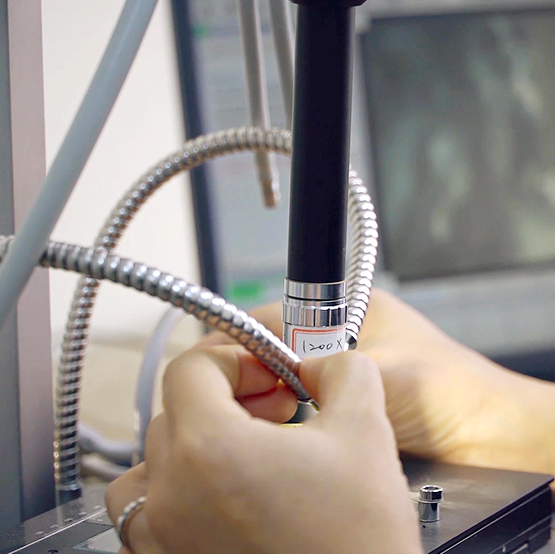

Quality Assurance

Moya is supplying OEM, Tier 1 and Tier 2 customers using ISO9001 and TS16949 based quality assurance systems. We also have the capability and experience to perform all environmental tests for PPAP approval level required by customers.

Concept design

Based on our long experience in designing a wide range of blow molding spoilers, MOYA provide the best design to meet customer needs. MOYA provides the best design for products to meet Aero-dynamics elements and various regulations, while enhancing the styling of the vehicle.

Engineering Design

Based on more than 25 years of experience in blow molding engineering design, MOYA does product design to reflect the our customer’s concept design. Our experience and patents give Moya a competitive advantage to develop and manufacture advanced and novel designs. Moya’s team of design, tooling, molding and production engineers collaborate to evaluate all the steps to produce the part from mold design to check fixture design and packaging.

Prototyping

Based on the concept design, we build prototype samples to confirm our engineering designs before making the mold and going into production. By checking the samples in real size before building the mold, we can check the surface match with the vehicle, find potential assembly problems, develop packaging and confirm compatibility with various processes before mass production.

Tool Design

The mold design is optimized for the blow molding to produce a high quality part and built based on many years of Moya experience and patents available.

Blow Molding

Blow molding is a process to make plastic products with hollow structures. A hollow tube of molten plastic (parison) is extruded from the blow molder. The mold is closed around the parison and blow needles penetrate the parison to inflate it to the shape of the mold. The material is cooled, then the part is removed from the mold and trimmed. The hollow blow molded part is one piece and does not require bonding of two halves like the injection molded process. Blow molding has many advantages in strength, design, part reduction and assembly. Blow molds are less expensive than injection molds for the same finished shape. Moya has supplied the best world class blow molded spoilers and parts for 25 years.

Sanding

Sanding the surface of the blow molded product makes the optimal surface condition for painting. MOYA has a long experience and know-how preparing the surface for good paint adhesion and a Class ”A” finish.

Painting

Moya operates two independent conveyor painting lines: top loading method and a floor loading method. Both painting lines are operated with top OEM quality painting levels and optimized for each product shape and painting method. With over 20 years of experience, our highly trained engineers and workers produce the best results for each product with our craftsmanship.

Quality Assurance

Moya is supplying OEM, Tier 1 and Tier 2 customers using ISO9001 and TS16949 based quality assurance systems. We also have the capability and experience to perform all environmental tests for PPAP approval level required by customers.